I always like a challenge and this is a great example. A worn out bike and 45 days!

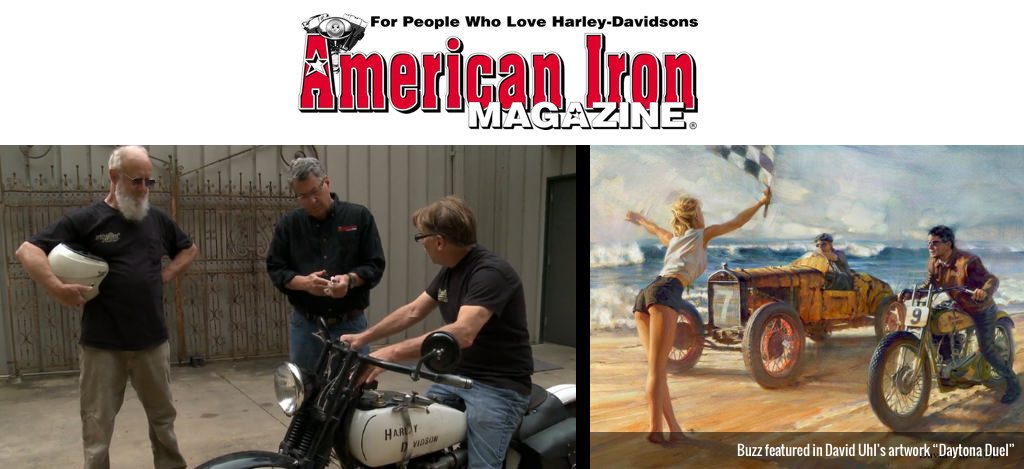

But this is not the first time Buzz has thrown me a challenge. I almost can’t count, but the pot of gold at the end of the rainbow is always a great finish and some ink in American Iron magazine. American Iron, for those not in the know- is the largest news stand cycle magazine in the country. Good ink is always good, GREAT ink is always GREAT!

Looking back, there have been some memorable builds with Buzz. In 2010, Buzz and I each raced 1915 Harleys across America from Kitty Hawk NC to Santa Monica, CA in the Motorcycle Cannonball. In 2012, he raced across America again in the Cannonball with his other Two Cam Harley. Once, Buzz had me revive a 1924 Harley that was great fun considering the old girl had not run in 50 or 60 years. There has been old bikes made to look like new, and new bikes made to look old.

But back to this one- The ultra-rare 1929 Harley JDH Two Cam. Approx. 2000 of these machines were made in 1928 and 1929 only. Many of these machines were hot rodded like this one. They were built as reliable, fast machines consequently they got used up, abused and eventually became extinct. The few surviving examples have been scooped up by collectors and some examples have sold for well over 100k.

What we started with was actually a pretty good start. The bent frame is pretty common. Remember these machines were raced! With the limited time at hand, it became an exercise in precise calculation of what parts get what finish. The big credit goes to John Dills who painted the bike in luscious two tone maroon. I believe there were over 22 individual parts that got the glowing maroon Matrix paint. Oops, forgot to mention the 15 or so parts that were sprayed in jet black to compliment the maroon.

Now, I love the fact that the History channel allows me to share our passion with the world, but what the viewers did not see is the work of fine artist Mark Peters from Asheville, NC, who did the intricate detail work pin striping over 27 feet of freehand and the incredible lettering. I truly wish his multifaceted talent is filmed on future episodes of the show. (BTW Mark did the work on MR. Lucky bike).

Back to the bike. Many of the parts were nickel plated. This process puts a micro layer of nickel on iron and steel parts. My pals at Plating Specialties in Michigan supplied that work in short order. They did me a huge favor by cleaning the parts prior to plating saving me 20 or so hours.

As you saw on the show, we stripped the tanks, but after a close examination we opted for tanks that have welded seams. These tanks are supplied and produced by my pal Tom Feezer at Replicant Metals in PA. He makes, sells, and distributes a huge range of parts for Harleys from 1910- 1948 AND MORE.

Some of the unusual details of this old hot rod bike go like this. The front wheel had a massive non Harley brake put on likely in the 60s. The front wheel is attached to a fork that dates at least 4 years from the year of the frame. This is where it gets interesting, meaning it does not handle like a 1929 road bike. It handles more like a 1940 s dirt track 750 Harley racing machine. Ah, the handlebars are next. Hand built in one week by the talented Tom Faber who is in the business of making handlebars for Harley Davidson motorcycles from 1909 to the 50s. Hundreds of styles, thousands of bends. I have used Tom’s bars on bikes I race/ride and put my life on the line. They never fail and are always perfect. No simple task! Faber Machine!!

I forgot to mention the wheel rings. If you noticed the wheels/rims were in good shape but in need of restoration. WE CHEATED. We cleaned them up. Touched them up, and the magic. Back in the day you could purchase 2 inch wheel rings. They were aftermarket parts made to give your bike that extra snaz. These re-manufactured rings were made at great expense by my friend Matt Olsen in Aberdeen, SD. Matt and his dad Carl have been restoring Harleys to the highest standards for years. Well it all came together. Painted in the lighter maroon and striped by Peters. It was a great way to save $ without compromising appearance. So much for detail!

I forgot to mention the wheel rings. If you noticed the wheels/rims were in good shape but in need of restoration. WE CHEATED. We cleaned them up. Touched them up, and the magic. Back in the day you could purchase 2 inch wheel rings. They were aftermarket parts made to give your bike that extra snaz. These re-manufactured rings were made at great expense by my friend Matt Olsen in Aberdeen, SD. Matt and his dad Carl have been restoring Harleys to the highest standards for years. Well it all came together. Painted in the lighter maroon and striped by Peters. It was a great way to save $ without compromising appearance. So much for detail!

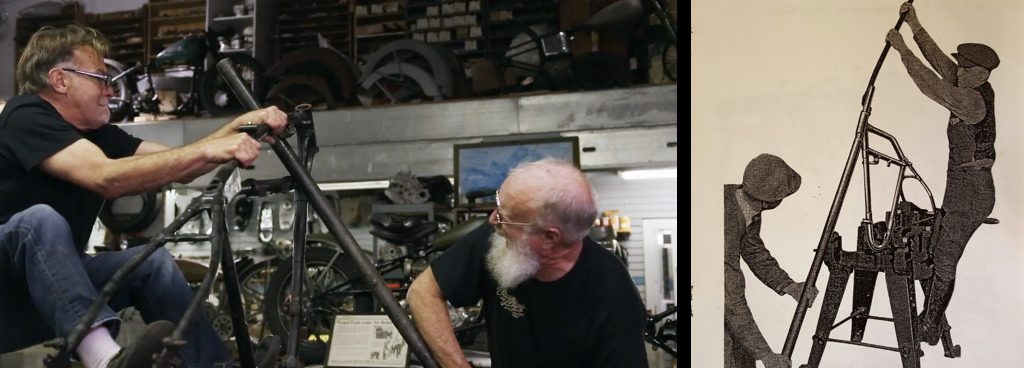

The work started with the tear down. It was late and the hardworking film crew had their 12 hours in, so they left a young and talented shooter. He did not work long. We took it apart in about 45 minutes. And the bent frame. It sure as heck was off. The beauty was the genuine 1922 Harley frame table we have on hand for such a task… The fork was bent also and the same table facilitated a quick fix. The reassembly went well. I used very little of the nut and bolt crappy (I mean crappy) hardware and replaced it with left over nickel bolts and nuts from my Crocker project and a few other leftovers.

The real challenge is doing a bike in short time is all the plating and painting coming back in the right order to finish the job on time. It all was coming together and then one late night while installing the most critical, up front visual part, the right gas tank. The tank had come from PA late! John did the paint and decal but then off to the stripper for the gorgeous thin stripes. Back to John for clear coat. A thousand miles later here we go and then SH**-. I was trying to align a top bolt with a punch and pushed too hard, snapped the punch and gouged the paint to the metal. Three days before the ride up Maggie Mountain, John Dills and Mark Peters were back to work. About 200 miles back/forth and around. I was more careful the second time and the installation was filmed. I was nervous.

The kick starter. I kind of figured this would happen. We dumped the crappy single tube pipe and opted for some custom made duels and added some fun by installing some Indian DNA to the bike. Thanks to Jerry Greer in Sturgis, SD. His company Jerry Greer’s Engineering manufactures an enormous line of Indian replacement parts from the 30s, 40s, and 50s. And they are all perfect. Every one! The high quality fishtails for the tips of the pipes were finished in clear lacquer only so they would have a profound look after 100 or so miles… I really think they make a statement right out of the 30s.Back to the kick starter arm. It is made by my pal Michael Breeding in Santa Fe, New Mexico. He is among the most talented fabricators of cast steel and forged steel replacement parts for Harley Davidson from 1909 through 1940s and more of course. One of the many great things about Michael is he started making Indian parts 40 years ago. Mastered that, sold the line and did the same damn thing with Harleys. Epic.

The kick starter. I kind of figured this would happen. We dumped the crappy single tube pipe and opted for some custom made duels and added some fun by installing some Indian DNA to the bike. Thanks to Jerry Greer in Sturgis, SD. His company Jerry Greer’s Engineering manufactures an enormous line of Indian replacement parts from the 30s, 40s, and 50s. And they are all perfect. Every one! The high quality fishtails for the tips of the pipes were finished in clear lacquer only so they would have a profound look after 100 or so miles… I really think they make a statement right out of the 30s.Back to the kick starter arm. It is made by my pal Michael Breeding in Santa Fe, New Mexico. He is among the most talented fabricators of cast steel and forged steel replacement parts for Harley Davidson from 1909 through 1940s and more of course. One of the many great things about Michael is he started making Indian parts 40 years ago. Mastered that, sold the line and did the same damn thing with Harleys. Epic.

Anyhow I knew the arm was going to be perfect. But I did not expect the bushing to be undersized. We were really about a day out and it was nothing short of a miracle to have a Stone Age tool exactly the right size! It all came together to the day. The reveal was fun, the motor was dead cold and did start on the first kick. Buzz was truly impressed and that was the goal.

The ride was short but real and someday there will be a story in American Iron Magazine.

-Dale Walksler

Many people contributed to the success of this project, we would sincerely like to thank everyone involved. Just to name a few:

Many people contributed to the success of this project, we would sincerely like to thank everyone involved. Just to name a few:

Buzz Kanter – American Iron Magazine – www.aimag.com

John Dills- Dills Paintworks- Sylva, NC – www.dillspaintworks.blogsot.com

Mark Peters- Peters Auto Art- Asheville, NC – www.petersautoart.com

Plating Specialties Inc. -Madison Heights, MI – www.platspec.com

Tom Feezer- Replicant Metals- Lancaster County, PA – www.replicantmetals.com

Michael Breeding- Sante Fe, NM – www.mikespartsforharleys.com

Tom Faber- Cedar Springs, MI – www.fabercycle.com

Matt & Carl Olson- Aberdeen, SD – www.carlscyclesupply.com

Jerry Greer’s Engineering – www.jerrygreersengineering.com